September 2023

Project Overview

The Automatic Fluid and Powder Dispenser was designed to streamline the preparation of naloxone hydrochloride solutions

for emergency overdose treatment. Traditional manual mixing is time-consuming, inconsistent,

and poses health risks through direct handling. This project aimed to create a compact device that could automatically measure,

dispense, and mix powder with water inside test tubes in under two minutes. The system combined a rotating turntable, a peristaltic

water pump, a servo-controlled powder funnel, and an Arduino microcontroller for precise timing and operation. For safety during

prototype testing, the active pharmaceutical ingredient was substituted with Kool-Aid powder and water, allowing the team to safely

validate the device’s functionality and reliability. By simplifying the process into an automated sequence, the dispenser

demonstrated how low-cost engineering solutions can improve safety, reliability, and efficiency in pharmaceutical preparation.

• Develop a device capable of automatically preparing naloxone hydrochloride solutions to assist in overdose treatment.

• Design a system that can dispense both powder and water into test tubes within 120 seconds.

• Ensure the dispenser remains within specified dimension limits of 25 cm × 25 cm × 30 cm for portability and ease of integration.

• Incorporate four integrated subsystems:

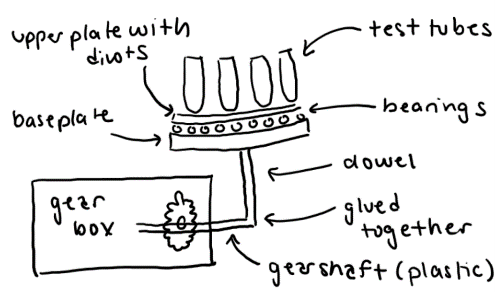

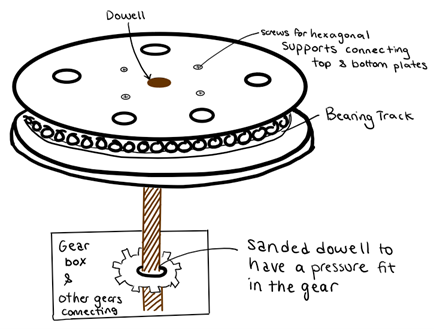

→ A rotating turntable to align and position test tubes.

→ A peristaltic water pump to deliver precise volumes of fluid.

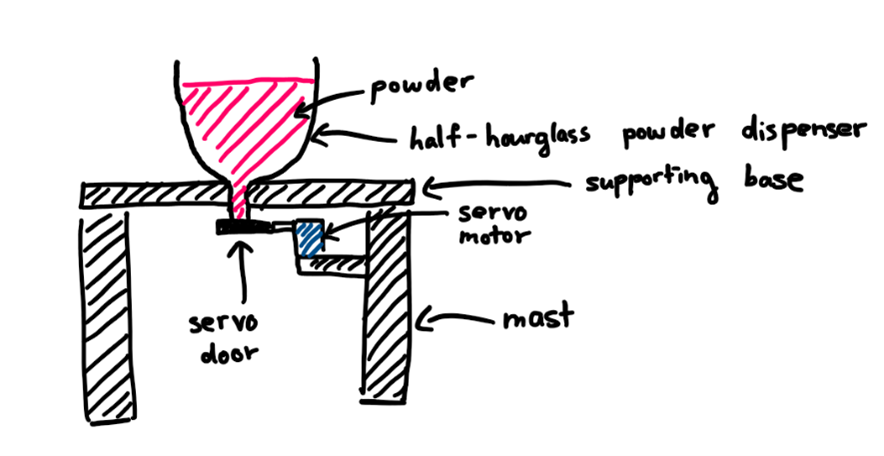

→ A servo-controlled powder funnel to release accurate doses of powder.

→ An Arduino-based control unit to automate timing and sequencing.

• Ensure the design is compact, portable, and user-friendly, requiring only the push of a button to operate.

• Build in safety features, including an emergency stop mechanism, to minimize risks during operation.

• Utilize sustainable and low-cost materials (recycled cardboard, acrylic, simple electronics) for prototyping.

• Test the prototype safely by substituting naloxone powder with Kool-Aid powder and water to demonstrate functionality.

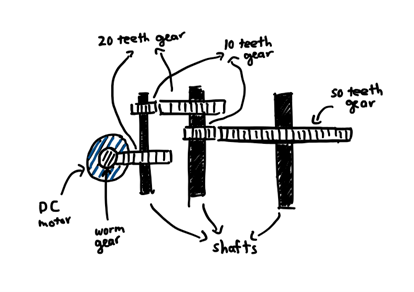

The design process began with brainstorming and initial concept sketches to identify possible ways of combining powder and

liquid automatically. Early ideas included immersion-based mixing, screw-driven funnels, and rotating hoppers. After

evaluating complexity, stability, and manufacturability, the team selected a turntable-based system that would align test

tubes under separate dispensing units. This allowed powder and water to be delivered sequentially with fewer moving parts.

From there, dispenser parts were created to size the system within the required 25 cm × 25 cm × 30 cm dimension limits.

Cardboard and foamboard models were used to test tube alignment, subsystem layout, and stability. These mockups revealed that

immersion-style mixing was not reliable at small scale, leading to the simpler funnel-based powder dispensing approach.

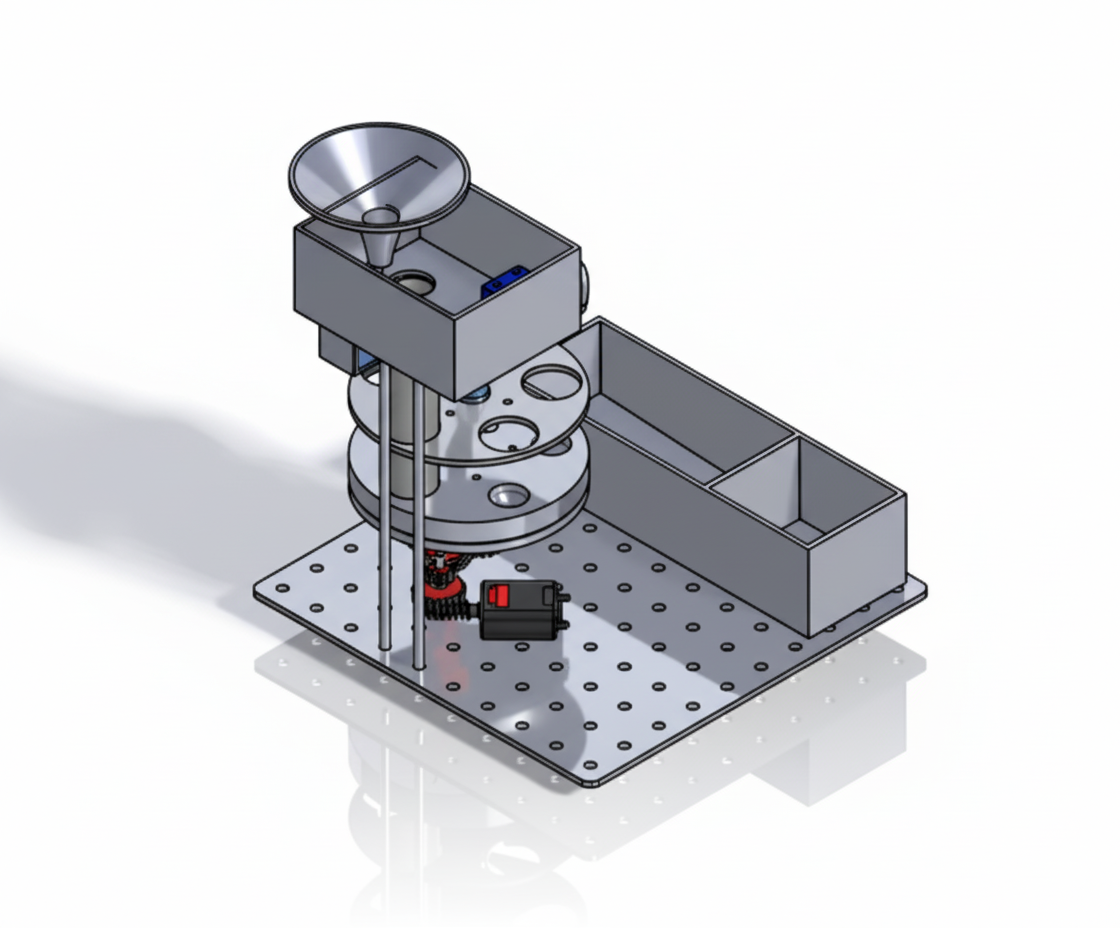

The next stage focused on CAD modeling in SolidWorks. Each subsystem was designed parametrically to allow quick changes in dimensions.

The turntable was modeled with a central shaft and evenly spaced slots for test tubes. The powder dispenser used a servo-controlled

trap door funnel that released a fixed amount of powder per actuation. A peristaltic pump was modeled for water delivery to ensure

consistent volumes while avoiding contamination. All subsystems were integrated into a single frame to ensure proper clearances and

manufacturability.

Once the CAD model was complete, the design was refined through iteration and simplification. The shaft connection for the

turntable was improved to reduce wobble, and the powder funnel was streamlined to prevent clumping. Fillets and reinforcements

were added at high-stress regions to reduce material failure risk. The overall frame was reduced to a compact rectangular base to

stay within size constraints and improve portability.

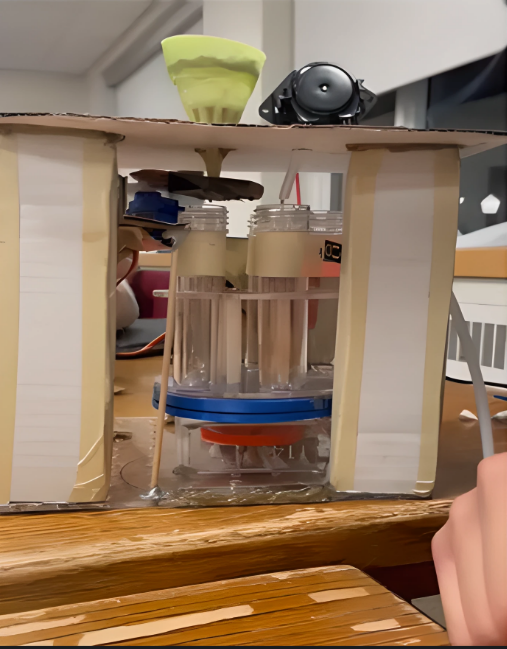

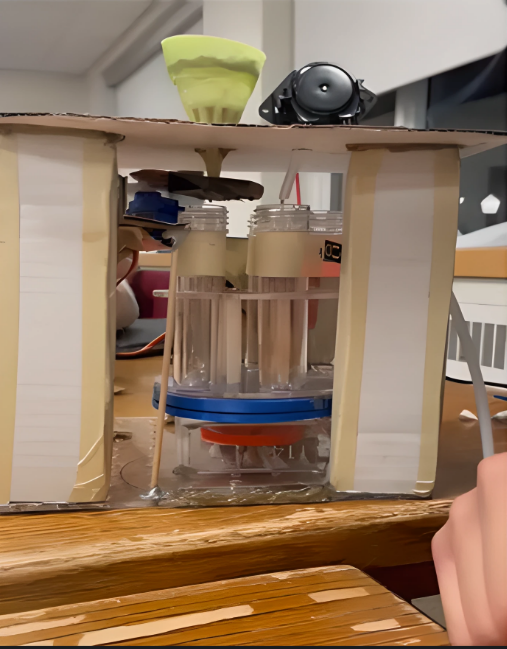

Finally, the design was implemented through rapid prototyping and electronics integration.

Laser-cut acrylic and recycled cardboard were used for the frame. An Arduino Uno was programmed to control

the motorized turntable, servo motor, and water pump in sequence, with an emergency stop button included for safety.

For testing, Kool-Aid powder and water were substituted in place of naloxone to validate system performance without handling

pharmaceuticals.

Iteration and Design Challenges

One of the most significant challenges encountered during the assembly of the final prototype occurred in the

gearbox subsystem. During the physical build, the team discovered that the spacing between the axle holes

had been miscalculated in the original CAD design. As a result, the holes were placed too far apart,

preventing the gear teeth from meshing correctly. This created a major mechanical failure — the gears were

unable to transfer motion, leaving the entire drivetrain disconnected and the turntable inoperative.

Due to time constraints and limited access to fabrication resources, reprinting the gearbox casing was not a

feasible option. The enclosure was made of acrylic polymer, which provided an opportunity to apply material

science principles to solve the issue. Knowing that heat softens the internal bonds of polymers, the team

used a lighter to carefully heat the acrylic around the misaligned hole locations. Once the material reached

a pliable state, a drill was used to accurately reposition the holes at the correct spacing. This solution

required careful measurement and steady execution to avoid cracking or warping the enclosure.

After the new holes were created and the gearbox was reassembled, the gear teeth engaged properly, restoring

full functionality to the drivetrain. The turntable began rotating as intended, and the DC motor’s power was

successfully transmitted through the gear system. This experience highlighted the importance of precision

in mechanical design and demonstrated the team’s ability to adapt and apply theoretical knowledge to

overcome real-world engineering challenges under tight constraints.

Final Prototype and Technical Specifications

The final prototype of the Automated Fluid and Powder Dispenser is a compact, autonomous system that prepares aqueous naloxone solutions at the push of a button. It integrates four coordinated subsystems — rotation, powder dispensing, liquid delivery, and electronic control — into a single, sealed unit designed for safety, precision, and ease of use. Each subsystem was optimized through iterative design to reduce mechanical complexity, improve reliability, and meet the 120-second dosage requirement.

Operation Process

When activated, the Arduino UNO initializes the dispensing cycle. The infrared sensor confirms test tube alignment before the turntable rotates into position. A servo motor then opens a funnel door approximately 80°, allowing a controlled dose of powder to fall into the tube. Immediately afterward, a DC-powered water pump delivers a measured volume of water from a sealed reservoir. Once the solution is prepared, the turntable indexes to the next tube and repeats the sequence. A double press of the start button triggers an emergency stop, halting all operations.

Subsystem Specifications

| Subsystem |

Technical Specifications |

Performance Notes |

| Turntable & Gearbox |

35 RPM DC motor with 1:200 gear reduction; 0.5 cm central shaft |

Rotates 1/5 turn per cycle with high torque for stable indexing |

| Powder Dispenser |

Servo-actuated 3D-printed funnel door (80° rotation), ~0.3 g/s flow |

Smooth funnel interior prevents clumping; thin door reduces spray |

| Liquid Delivery |

DC micro pump (~60 mL/min); ~20 mL delivered in 20 s per cycle |

Measured 200 mL in ~200 s; flow rate drops slightly after 2+ hours of use |

| Electronics & Control |

Arduino UNO with IR sensor, pushbutton control, and emergency stop |

Simple, programmable sequence; E-stop immediately cuts power |

| Frame & Materials |

PMMA acrylic structure, recycled cardboard prototype, sealed reservoir |

Corrosion-resistant and easily sanitized; sealed design prevents API exposure |

Performance Metrics

- Cycle Time: ≤ 120 seconds per tube

- Dispense Accuracy: ±5% volume tolerance in liquid delivery

- Powder Consistency: ±0.1 g per dispense cycle

- Safety Features: Sealed system, corrosion-resistant materials, double-press emergency stop

Overall, the final prototype demonstrated the ability to accurately and autonomously prepare multiple doses with minimal human intervention. Its modular design, compact footprint, and emphasis on safety and accessibility make it adaptable for pharmaceutical, clinical, and emergency response applications. Future iterations will focus on improving pump durability, adding a screw-cap sealed reservoir, and replacing temporary materials with stainless steel for long-term deployment.